Capturing the Prize: the A$200 billion opportunity for Australia's food and agribusiness sector / Enhanced Production and Value Addition / Sustainable Packaging

Extracting more value out of the supply chain by developing sustainable packaging through innovation, redesigns, light-weighting and ensuring packaging is reusable, recyclable or compostable.

Tomato growing company Kapiris Bros nurtures its produce across its lifecycle, from planting through to customer purchase. Their tomatoes retail at Woolworths. Growing awareness of the environmental impact of plastics coupled with consumer and retailer demand to do better prompted a rethink of their plastic packaging.

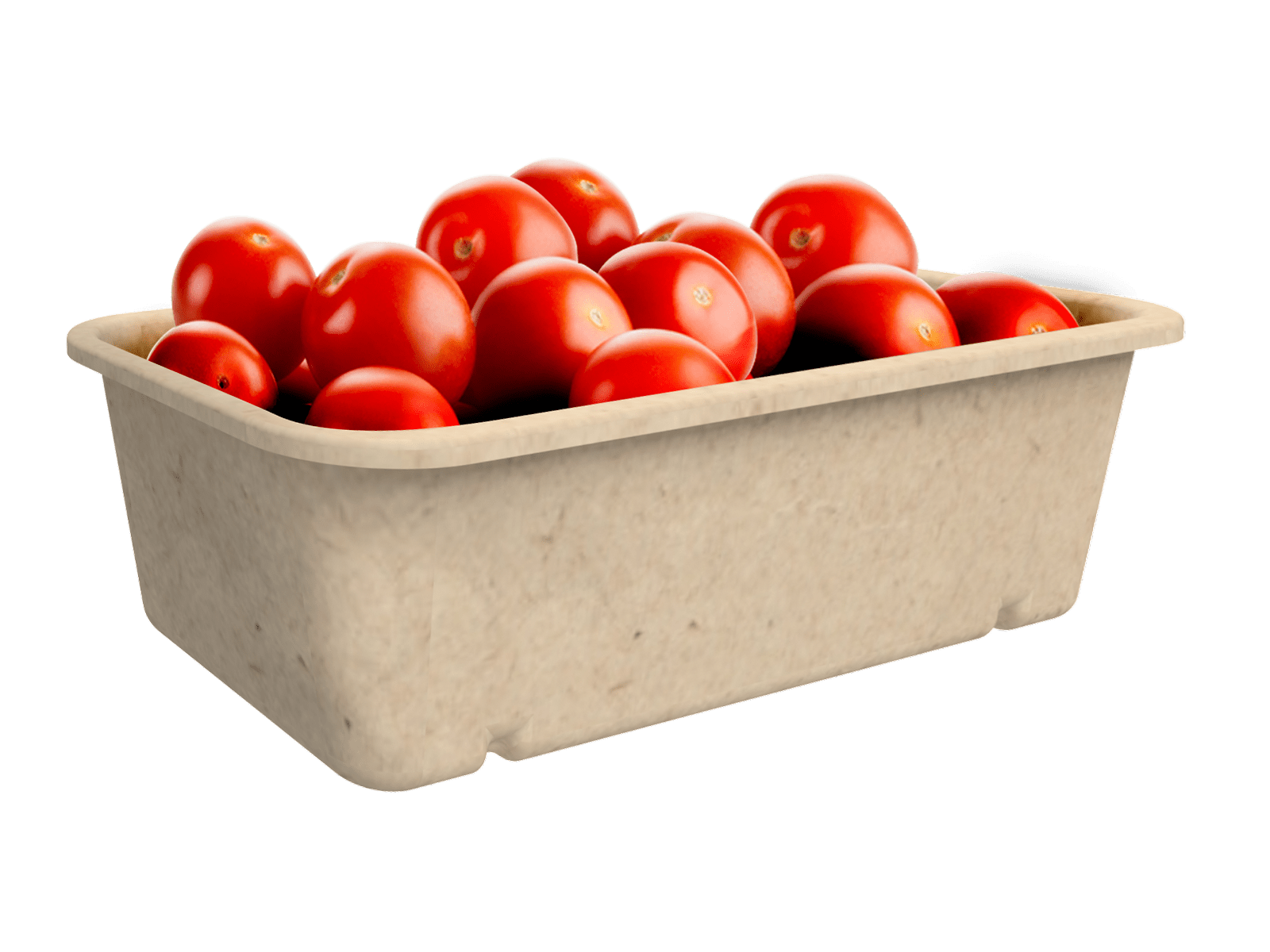

Working closely with BioPak they created a new tomato punnet design – a pulp tray made from bagasse (plant residue from sugar cane) and wheat straw. They are recyclable and home (AS5810) and industrially (AS4736) compostable to Australian Standards. Consumers can dispose of the packaging in either their paper recycling or home compost bin.

Switching from single-use plastic packaging derived from finite fossil resources to sugarcane packaging makes a big difference. For every 10 million tomato punnets made from sugarcane over conventional plastic packaging, 280,000 kilograms of fossil-fuel plastics will be avoided, and 744,155 kilograms of carbon emissions offset. As the tray is a natural material, it will not persist in the environment.

The packaging has been recognised with an Australasian Packaging Innovation & Design Award (PIDA) from the Australian Institute of Packaging (AIP).

The new tomato punnet design has boosted the sustainabllity credentials of Kapiris Bros and visually differentiated its brand from the competition. Its produce is a more attractive proposition for both the consumer and retailer – it helps Woolworths’ transition to recyclable, compostable, or reusable packaging by 2023.

The project formed a valued cross-functional relationship between Kapiris Bros, BioPak, and Woolworths, driving shared values to work towards Woolworths’ 2025 Sustainability Plan.

The new design needed to have the equivalent functional performance of the plastic containers previously used, protect the product, withstand the rigours of the cold chain, be easily integrated into the existing packaging process, and visually differentiate it from the competition. Industrial and graphic designers worked on the technical and aesthetic aspects from start to finish. Several prototypes were created throughout the development process to ensure there were no adverse functional or operational performance impacts.

Switching from plastic to pulp trays has avoided the use of 31.5 tonnes of plastic every year. This relatively simple swap in material shows how businesses can easily reduce their impact on the environment.

Woolworths have now adopted this design and made it mandatory for all their stores nationwide.

This case study is from FIAL's 2022 edition of Celebrating Australian Food and Agribusiness Innovations 2022