Capturing the Prize: the A$200 billion opportunity for Australia's food and agribusiness sector / Enhanced Production and Value Addition / Sustainable Packaging

Extracting more value out of the supply chain by developing sustainable packaging through innovation, redesigns, light-weighting and ensuring packaging is reusable, recyclable or compostable.

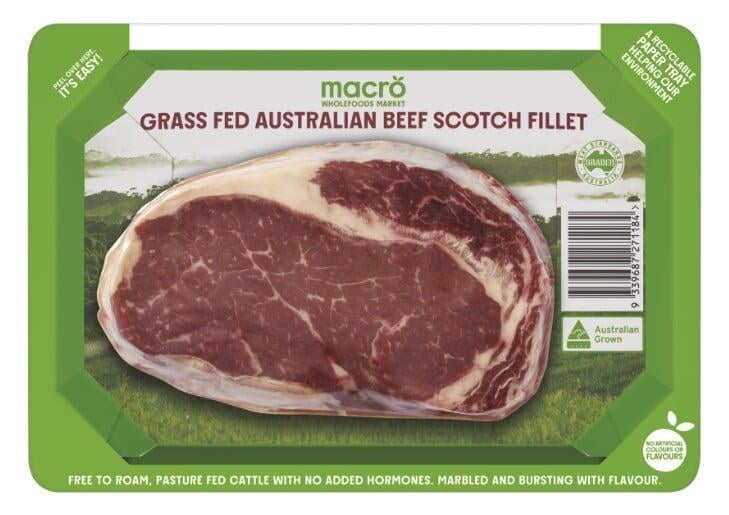

Woolworths is growing greener, and is committed to reducing plastic and making it easier for customers to recycle the packaging they take home with them. The retailer has committed to make 100 per cent of the packaging on its own brand products recyclable, compostable, or reusable by the end of 2023, and to halve the amount of virgin plastic used in own brand packaging by 2024. As part of its ongoing work to boost sustainability, Woolworths has recently redesigned its meat packaging.

It has created a PaperSeal Skin tray, used across seven popular beef cuts in the Woolworths Specially Selected and Grass-Fed beef range, which uses 75 per cent less plastic than previous packaging.

The single-piece tray is produced from renewable fibres from sustainably managed forests, with a barrier lining on the inside surface. The core of the tray is made from FSC-certified paper that can be recycled kerbside, with REDcycle compatible bottom and lidding film.

This new format has reduced the weight of packaging by 9.7g per tray – adding up to many tonnes of packaging materials per annum. This offers sustainability and operational benefits that cascade through the entire supply chain.

Clear recycling instructions with visual aids on the pack drive correct consumer behaviour, increasing the potential for a higher recycling and recovery rate.

It was recognised with an Australasian Packaging Innovation & Design Award (PIDA) from the Australian Institute of Packaging, and a silver Save Food Packaging special award and a general Food award in the prestigious global WorldStar Packaging Awards from the World Packaging Organisation (WPO).

The innovative PaperSeal Skin meat tray was the result of an extensive collaboration between Woolworths’ team members, trading partners, and packaging suppliers.

Its internal team – vertically and horizontally integrated – worked across quality, regulatory, commercial, artwork design, packaging and sustainability outcomes.

It worked with the PaperSeal® Skin tray supplier, responsible for the design and development of the fibre-based tray. This included the verification and validation of the design and testing protocols to qualify this innovation. The product manufacturer conducted production trials and transit tests, further coordinating with the Woolworths team for the microbiological and sensory testing.

The successful launch of the PaperSeal® Skin tray is not only about boosting sustainability, but also pushing boundaries collaboratively to create innovative design with a multitude of benefits.

This case study is from FIAL's 2022 edition of Celebrating Australian Food and Agribusiness Innovations 2022